The advantages of one piece TWB door ring

Leading hot stamping solutions

©2024 苏州普热斯勒科技股份有限公司 版权所有

Production

The advantages of one piece TWB door ring

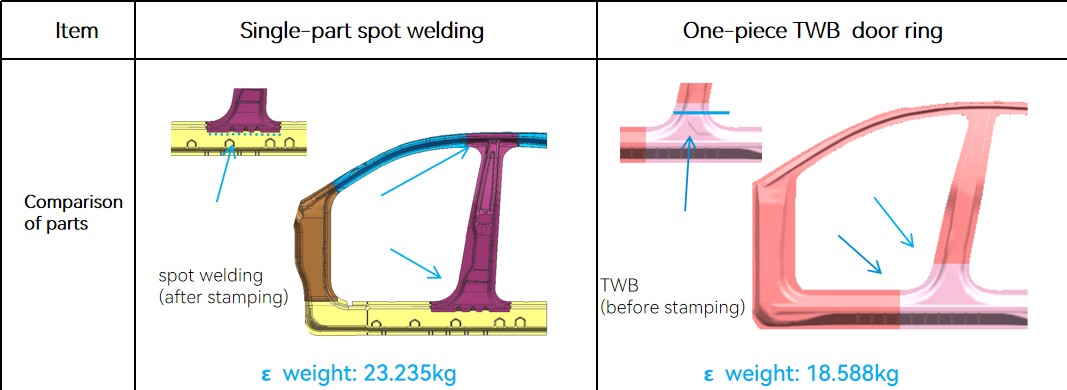

1.One part replaces multiple parts.

2.Only one hot forming die is used.

3.Only one hot forming is needed.

4.The TWB solution makes optimized material thickness and appropriate strength possible.

5.Less overlap in welding and lightweight parts with optimized material thickness.

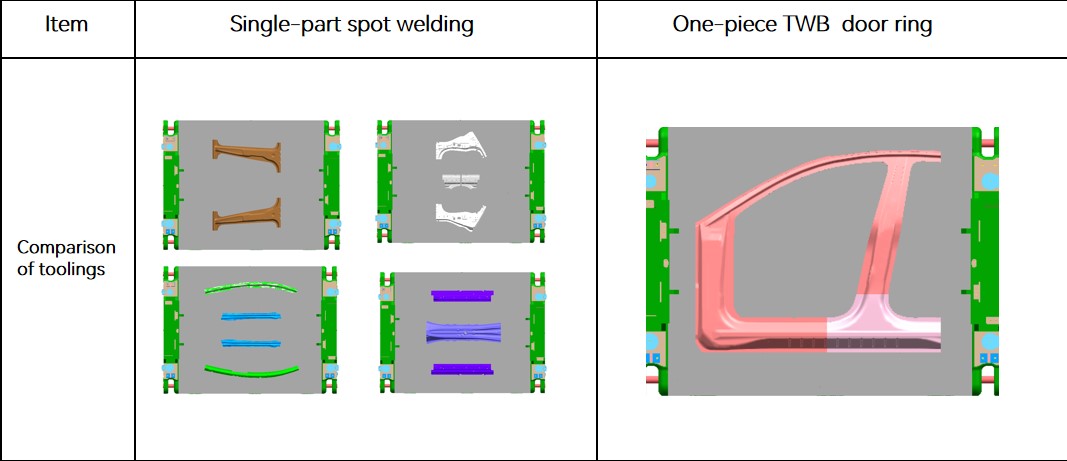

1.Reducing the number of toolings (Dies, inspection tools and fixtures)

2.Can reduce the cost of toolings by more than 20%.

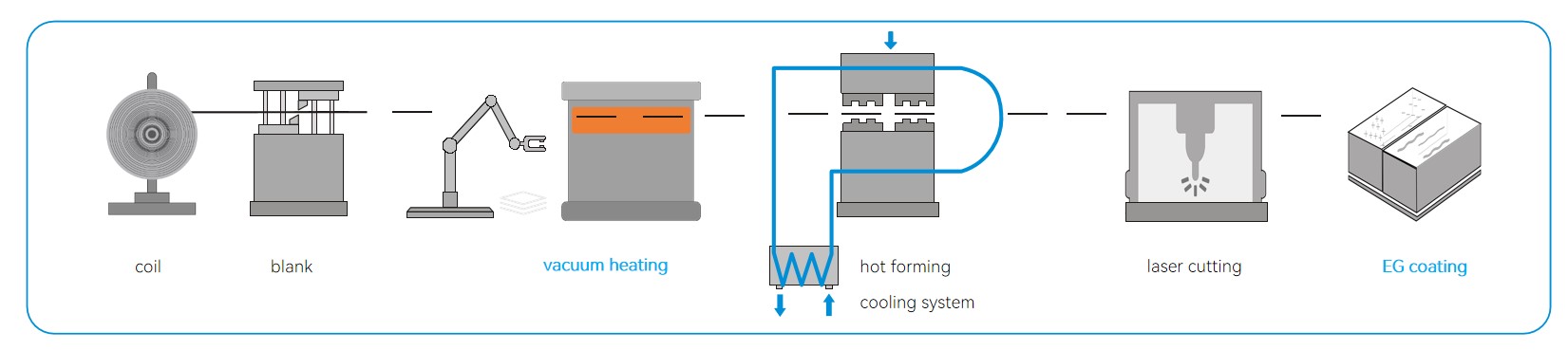

3.Given some problems in corrosion resistance of hot formed bare and aluminum-silicon blanks, brittleness of the Al-Si coating, and manual removal of spot welding burrs. Pressler introduces a new kind of process—all-in-one electric galvanized door rings. Using both vacuum hot forming and electro-galvanizing, this process forms the laser welded material with different hardness into door rings after heating at 930℃ before putting them into the electric galvanizing production line for degreasing, pickling, galvanizing, tempering and other processes.

Pressler’s Direct Hot Forming Process

What’s more, bare plates don’t need to remove their coating in laser welding compared with Al-Si coated plates, thus decreasing 10%-15% the cost of the all-in-one doorrings.

In addition, the electric galvanizing contributes to better corrosion resistance and resilience of the electric galvanized door ring, splash-free and burr-free in welding, improved production environment of the spot welding line, reduced rework of manual burr removal, decreased cost but improved security.

Advantages:

1.No patent limit in aluminium-silicon welding

2.Better anti-corrosion

3.Bigger welding window, no splash and burr, excellent welding performance

4.Better bending angle and impact energy absorption

5.No need for shot blasting, no worry for deformation

Steel battery pack

Steel battery pack