Introduction

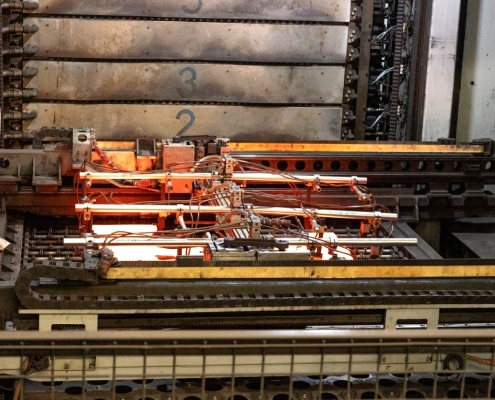

The core of the Pressler multi-layer roller hearth hot-pressing production line is a multi-layer roller hearth heating furnace. The multi-layer roller hearth heating furnace combines the advantages of traditional box furnaces and roller hearth furnaces. The 8-layer relatively independent furnace layer not only improves the efficiency of the heating furnace, but also takes into account the heat energy utilization rate of the heating furnace. The production line area is saved by 50%, the overflow area is reduced by 60%, and the cost of stamping production is reduced by more than 20%.