The production line with high flexibility and can meet customers’ various solution needs

Leading hot stamping solutions

©2024 苏州普热斯勒科技股份有限公司 版权所有

Production

1.The production line with high flexibility and can meet customers’ various solution needs

a.No need for mold investment, shorten the project development cycle.

b.No limitation for blank design and optimization.

c.Produce different shapes of the blank at the same time.

d.Can process different materials, like aluminum, high-strength steel, composite materials

e.Can switch production lines quickly for different types of products

2.Significantly improve material utilization and reduce material consumption

a.Highly flexible layout optimization, which can reducing waste.

b.Material consumption has decreased by more than 5% compared to traditional blanking.

c.Use rolls with more economical widths.

3.Cutting quality

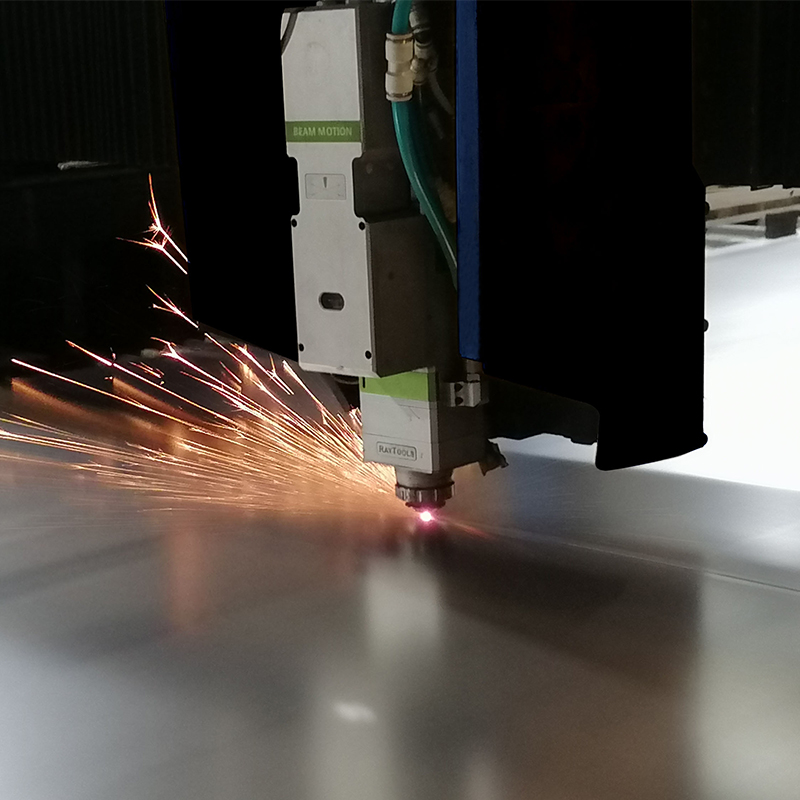

he laser cutting blanking line uses a non-contact method, utilizing a high-power density spot formed by focusing the laser beam to rapidly heat the material to the vaporization temperature, evaporating to form a small hole, and then moving the light beam relative to the material to obtain a narrow continuous cutting seam,to get the better edge cutting quality than that of the stamping blanking.

Six station laser cutting machine

Six station laser cutting machine