Leading hot stamping solutions

©2024 苏州普热斯勒科技股份有限公司 版权所有

Production

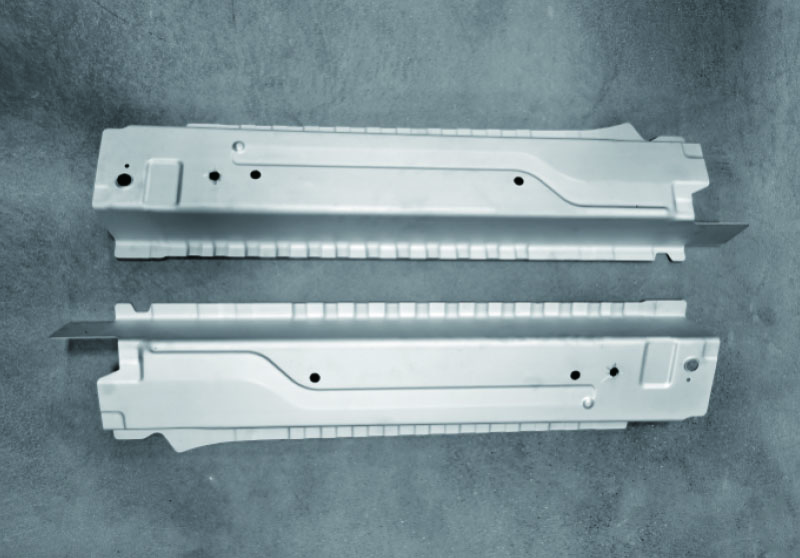

1.2000Mpa galvanized hot-formed parts

The 2000Mpa galvanized hot formed parts producing from Pressler vacuum heating furnace can increase the corrosion resistance of parts, improve weldability and reduce the risk of hydrogen brittlement.

2.2000MPa AI-Si coated hot-formed parts

The 2000Mpa AI-Si coated hot formed parts produced from Pressler vacuum heating furnace can prevent the aluminum-silicon from reacting with water vapor in the heating process to form hydrogen and reduce the risk of hydrogen embrittlement.

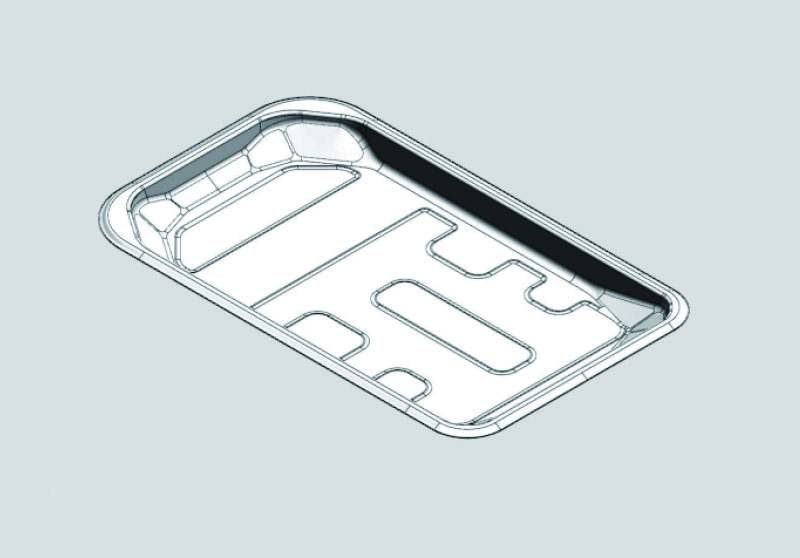

3.Integrated ultra-high-strength steel composite battery pack

The newly developed battery packs for the new energy vehicle industry have better fire resistance and crash protection. Its side wall is strengthened with hot forming materials for protection and collision performance.

Electro-galvanized hot-formed parts

Electro-galvanized hot-formed parts