A wealth of experience in hot forming enables mass production of various body-in-white parts possible.

Leading hot stamping solutions

©2024 苏州普热斯勒科技股份有限公司 版权所有

Production

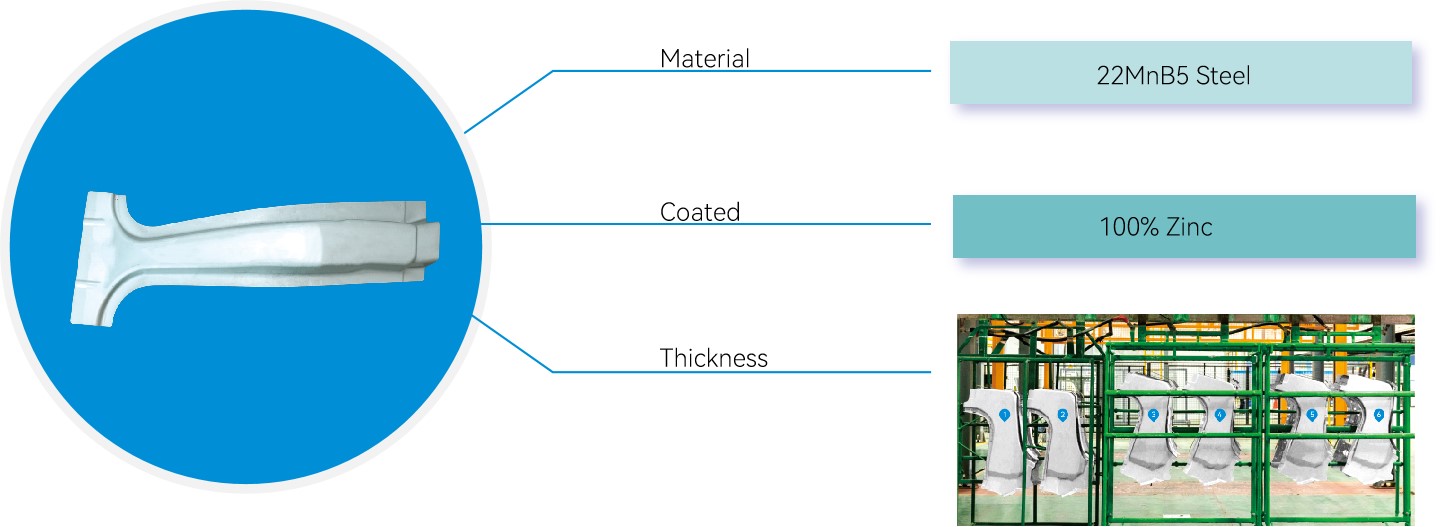

The tolerance of Pressler’s galvanized thickness is ±3um, and the thickness can be customized according to customers’ requirements.

The bending Angle of hot-formed galvanized parts is above 60 degrees, which is better than that of aluminum-silicon hot-formed products.

There is no coating cracking of the vacuum hot formed electrogalvanized parts and the three-point bending Angle of the 1.5mm sample is above 70 degrees.

Zinc coating is unaffected by heating, and it is dense, has good performance in anodic protection and corrosion resistance.

The welding window of galvanized hot formed steel is 2.8KA, and the welding window of aluminum-silicon hot formed steel is 0.6KA. In addition, there is no splashing or burring in the spot welding process.

The welding window of galvanized plate is 1.1KA and that of aluminum-silicon plate is 0KA . In addition, there is no splashing or burring during spot welding.

Vacuum hot forming line

Vacuum hot forming line