Automatic galvanizing line can meet the needs of automatic production, improve production efficiency, rate, using digital control system, to ensure the control ability of the production line.

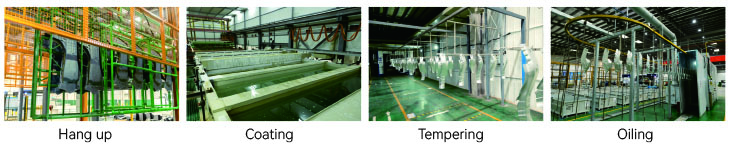

Coating line

Size: 100m*30m*8m

Capacity: 2.4 million pcs/year

Frequency: 30 flybar /3min

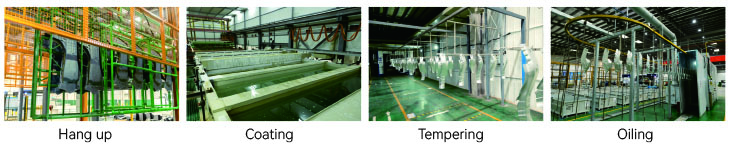

Tempering line

Size:75m*4.7m*1.75m

Capacity: 2.4 million pcs/year

Speed of chain drives : 0.5m(1.2 hanger)/min,≈10pcs/hanger

1.High degree of automation

By adopting highly automated process flow, from raw material input, EG treatment to finished product output, all can be achieved through automation control system, greatly reducing errors in manual operation and production process, improving production efficiency and product quality.

2.High production efficiency

By adopting a continuous production method, a large amount of raw materials can be processed quickly and efficiently, thereby improving production efficiency

3.Stable coating quality

The fully automatic EG production line adopts advanced galvanizing technology, which can ensure stable coating quality, such as coating thickness, adhesion and other indicators can reach a high level, thereby improving product quality and service life.

4.Strong controllability

By adopting a digital control system, various parameters in the production process can be monitored in real time, such as current, voltage, temperature, speed, etc., ensuring the stability and controllability of the production process

5.Environmental protection and energy conservation

By adopting advanced environmental protection technologies and energy-saving equipment, pollution and energy consumption can be reduced during the production process, which is in line with the trend of modern industrial development

Pressler’s laser blanking line

Pressler’s laser blanking line