Pressler Hot Forming Mold Factory was founded in 2014. Currently, it has an annual capacity of 80 sets of Hot forming molds. So far, hundreds of molds have been delivered to customers in and outside the Group. Our business covers preliminary SE analysis, mold design, manufacturing and commissioning. The product types include ordinary hot forming parts, TRB/TWB/PATCH plate hot forming parts, and inner and outer door ring hot forming molds. With excellent equipment and core professional technology, Pressler provides high-quality hot forming mold development and manufacturing for domestic and foreign customers. Under the philosophy of “customer first”, it wins customers and markets with competitive prices.

The tooling workshop is equipped with data processing equipment, including 10 sets of 5-axis deep drilling, 4 meters gantry CNC machining equipment, and 12 sets of small 850-CNC, which can complete the processing of all kinds of hot forming dies; Including two try-out lines (800T 400T), a self-developed heating furnace and blue light scanning equipment.

With an annual output of 80+ sets of hot-forming dies, Pressler tooling workshop provides hot-formed dies, die designing and manufacturing, small batch trial production, and after-sales integrated services, that’s why Pressler wins customers and markets giving the most competitive price and best quality.

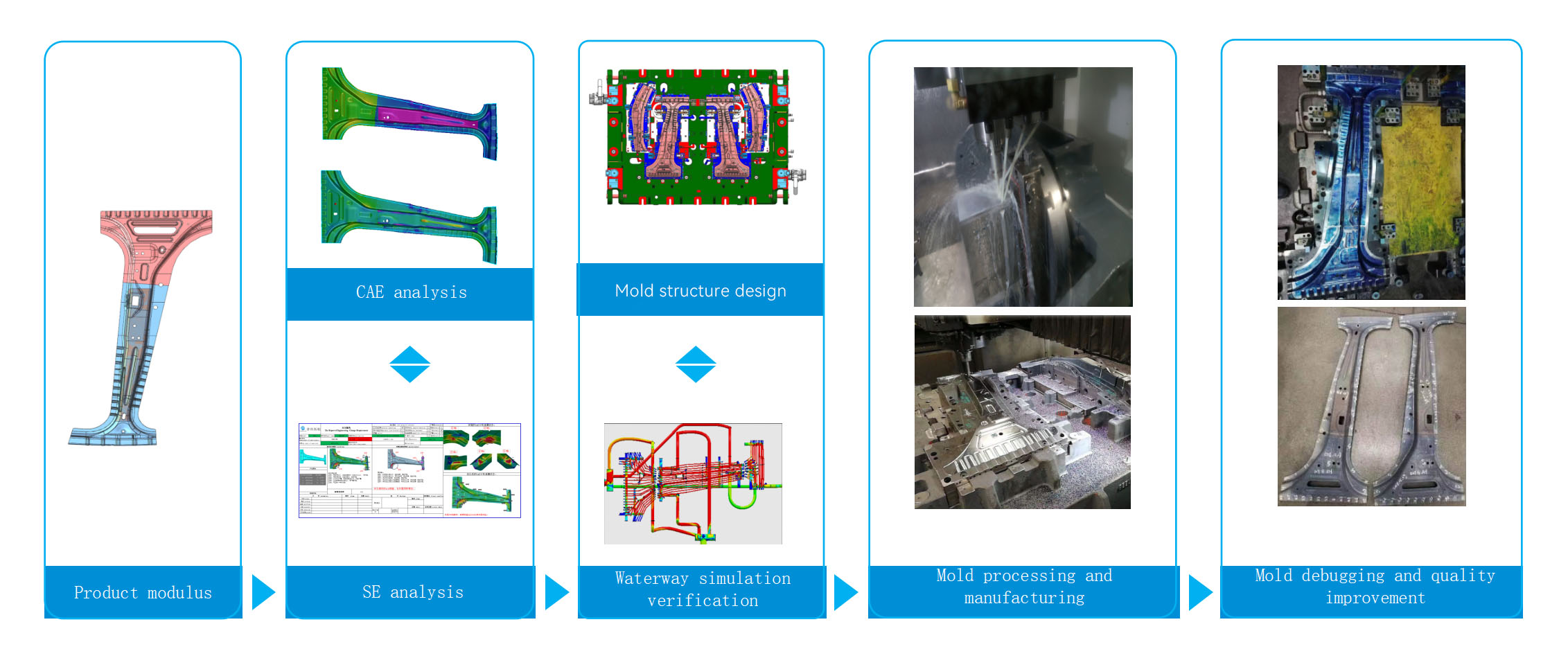

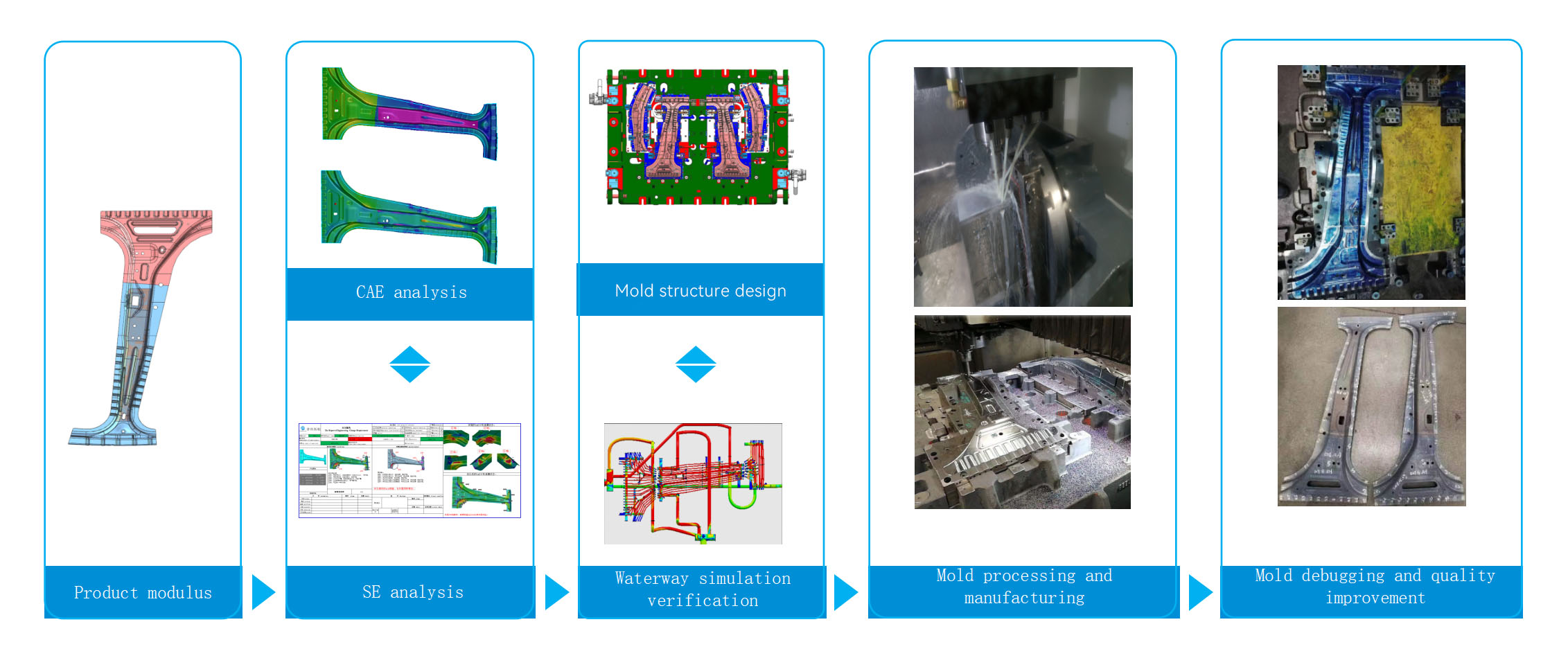

Mold development process

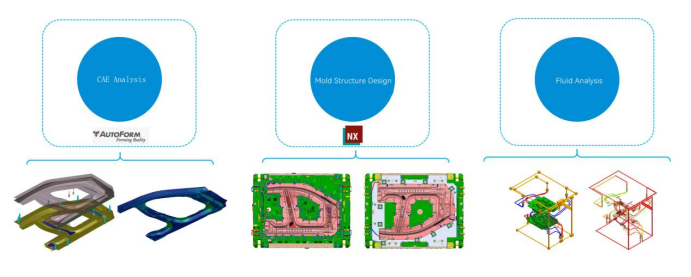

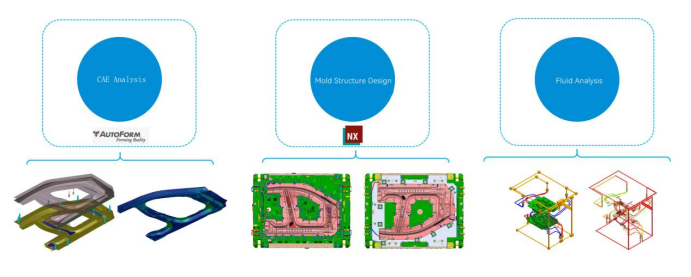

Mold design capacity

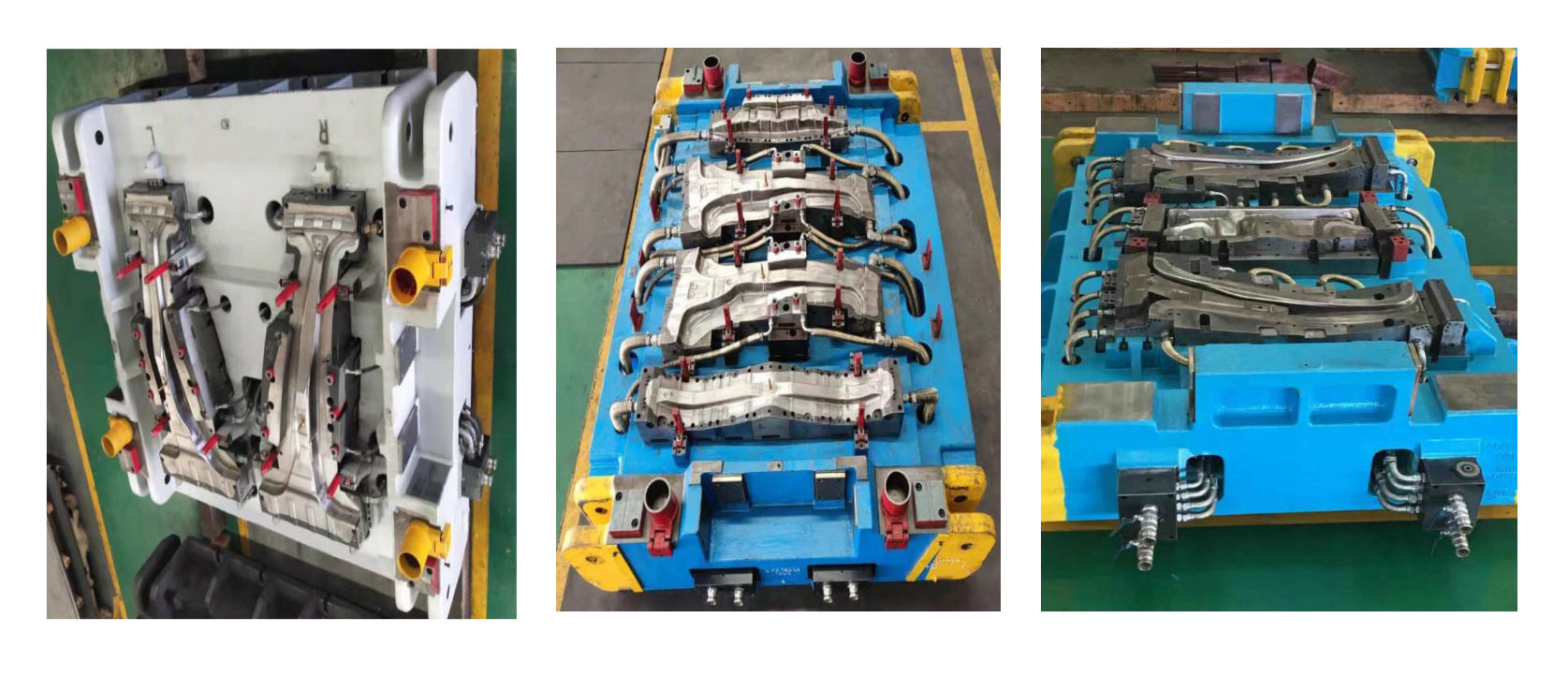

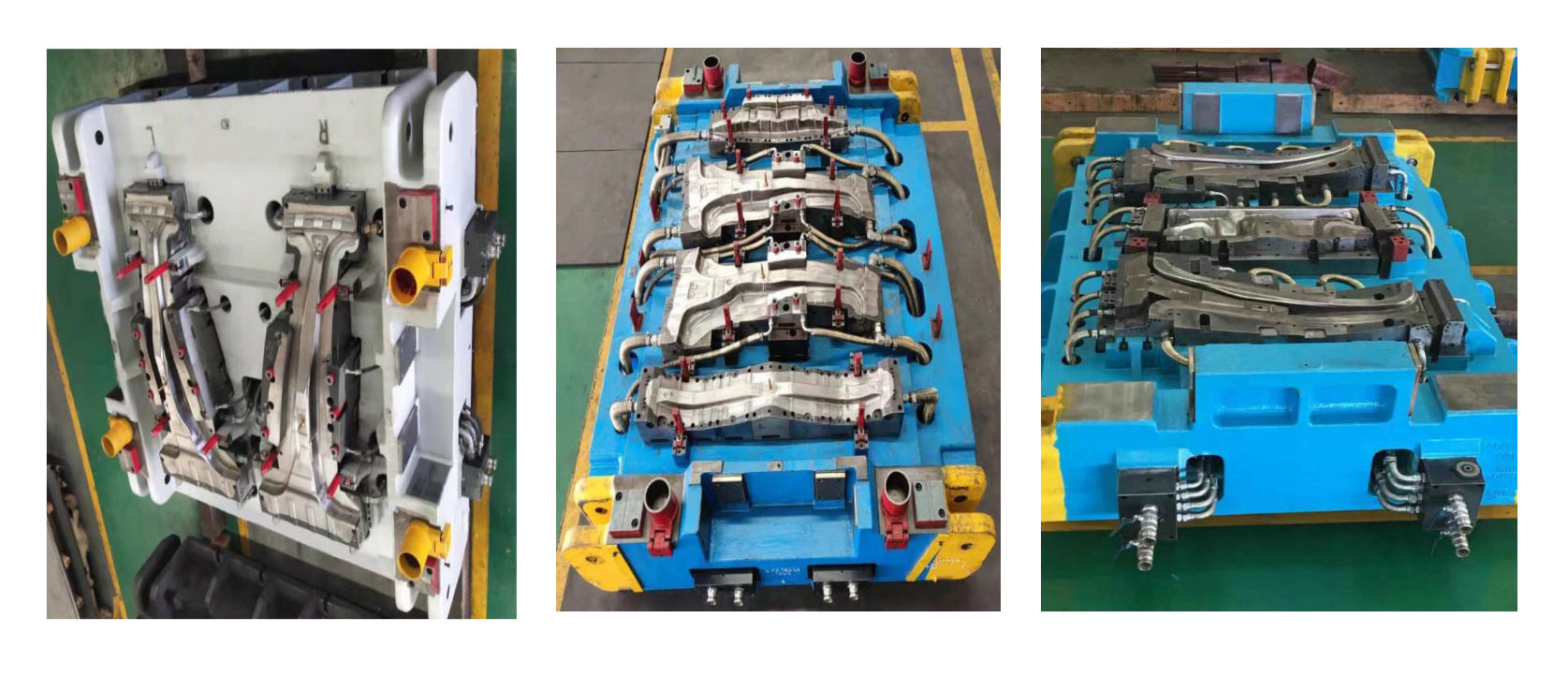

Mold manufacturing capacity

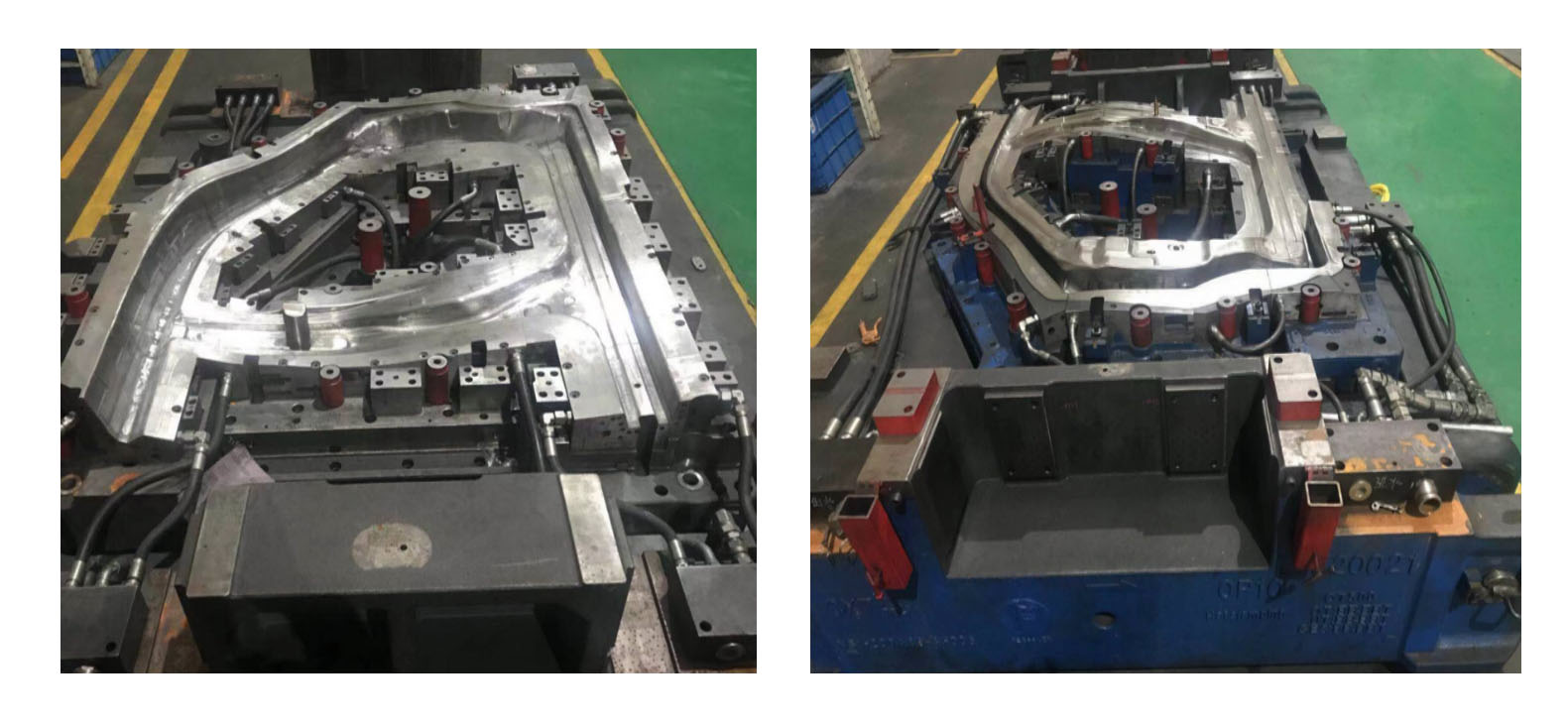

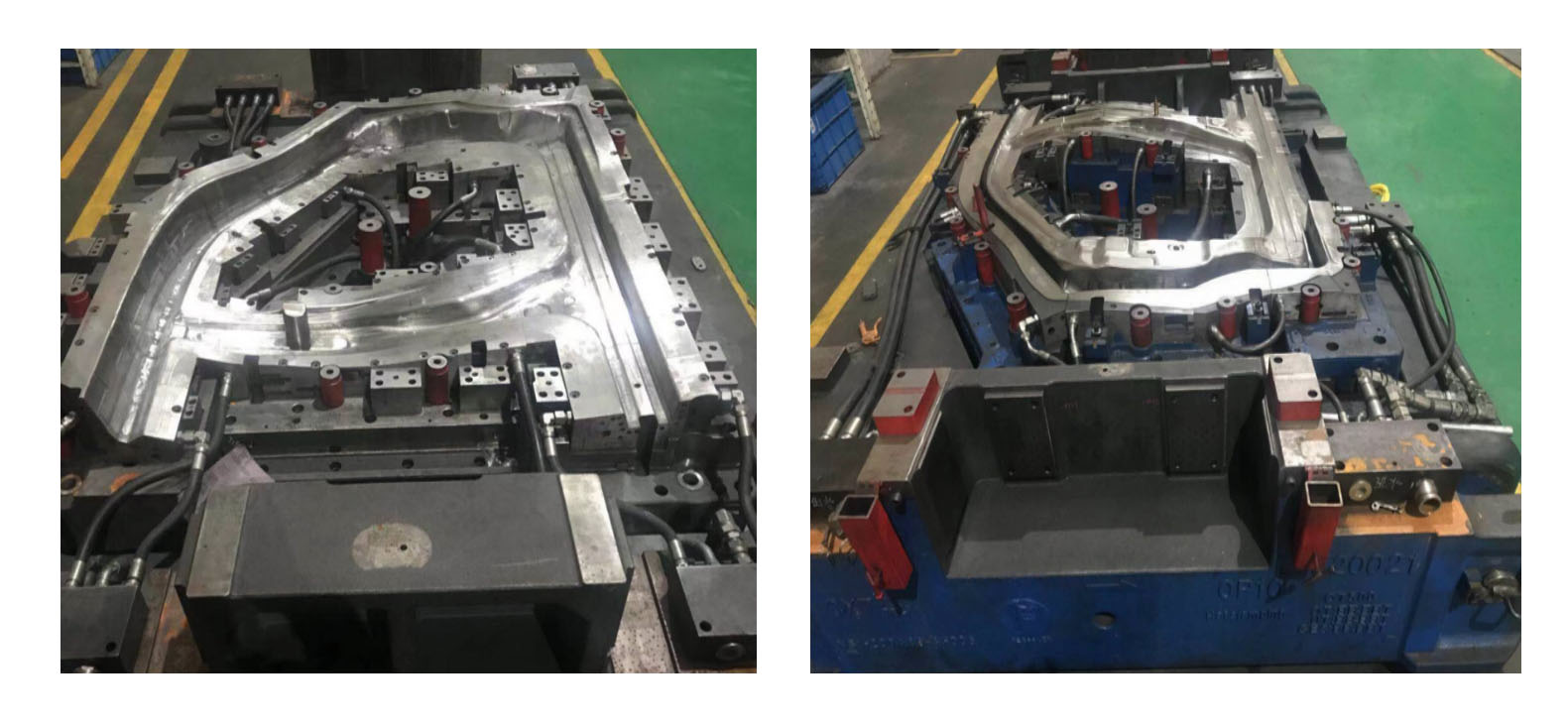

Mold debugging capacity

The mold fitter team in the debugging workshop has experience in mold debugging for several vehicle models, and has the ability to assemble, debug, and provide after-sales service for busbars;

The equipment workshop is equipped with 800T/1200T debugging press, heating furnace and automation.

Mold quality assurance

Some mold development cases

Customer:COSMA(CHONGQING)/

VW/SIMWON /

Great Wall Spotlight Automobile

Part name:B Pillar

Profile tolerance :±0.5mm

Customer:PRESSLER/ VW /JMCG

Part Name:Tunnel

Profile tolerance :±0.5mm

Customer:SIMWON /JMCG/BYD/SPOTLIGT

Part name: longitudinal beam

Profile Tolerance:±0.5mm

Dooring case 1

Customer:

Part name:Integrated door ring outer plate

Process:1 part per stroke

Note: Patch board+laser welding