Introduction

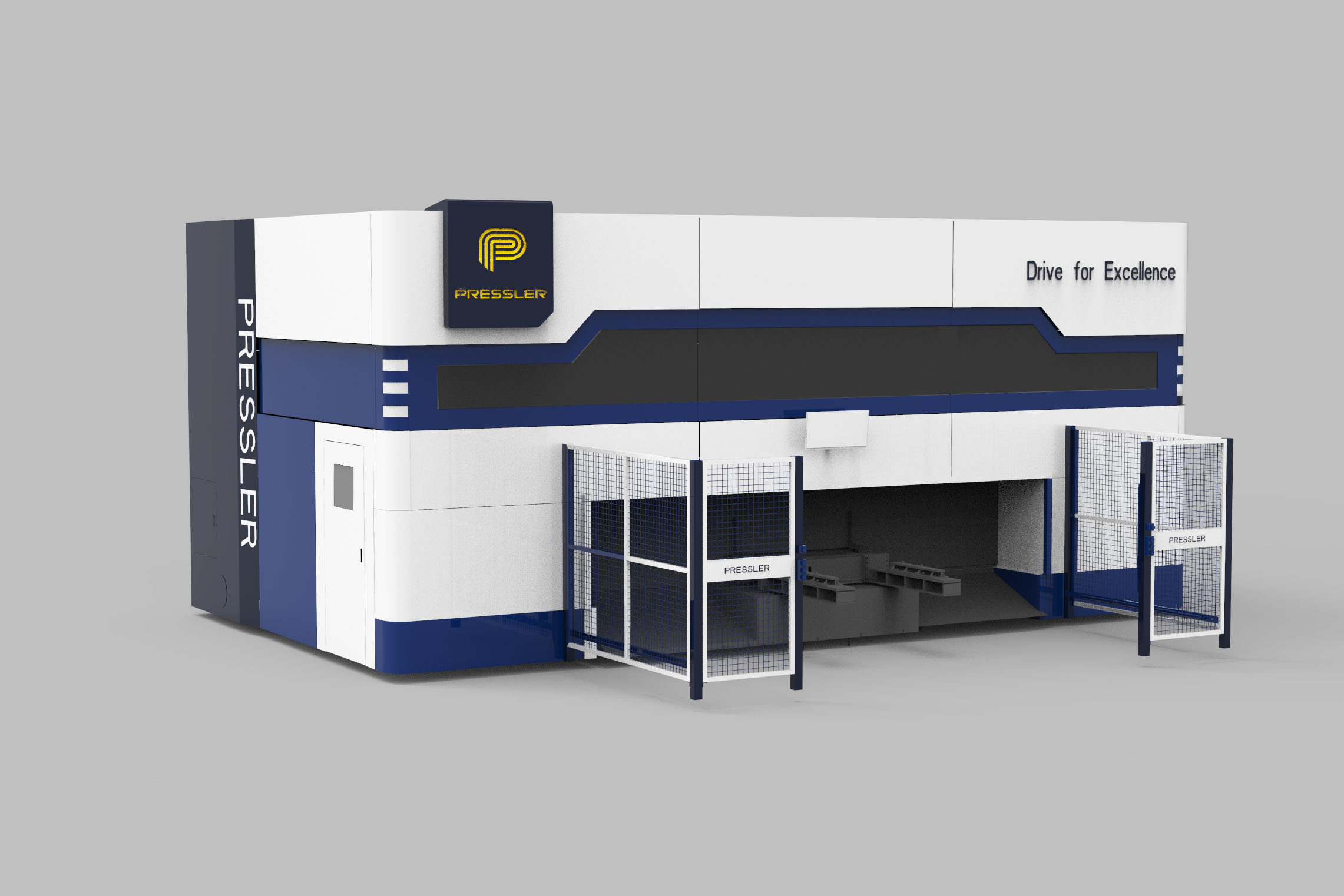

3D five axis laser cutting machine is a fast cutting equipment dedicated to automotive hot forming parts, with high cutting quality, safety and stability, which is suitable for 24-hour mass production.

Production

Technical parameters of five axis laser cutting machine

| Equipment type | FLP3019D-A |

| Laser power | 3000W |

| X-Axis Travel | 3000mm |

| Y-Axis Travel | 1900mm |

| Z-Axis Travel | 600mm |

| C-Axis Travel | n×360° |

| A-Axis Travel | ±135° |

| Floating axis travel | ±10mm |

| X,Y,Z axis positioning accuracy | ±0.05mm |

| X, Y, Z axis repeated positioning accuracy | ±0.03mm |

| C , A-axis positioning accuracy | ±0.015° |

| C, A-axis repeat positioning accuracy | ±0.005° |

| Exchange table positioning accuracy | ≤±15” |

| Exchange table repeated positioning accuracy | ≤±10” |

| Single axis max positioning speed (X、Y、Z) | 80m/min |

| Single axis max acceleration (X、Y、Z) | 0.8G |

| C axis max positioning speed | 80r/min |

| A axis max positioning speed | 120r/min |

| C-axis max acceleration | 60rad/S² |

| A -axis max acceleration | 120rad/S² |

| Single side maximum load | 350kg |

| Exchange table rotation time | 4~5S(According to changes in load) |

| Machine weight (excluding outer cover and turntable) | 14000kg |

| Dimensions (length x width x height) | 8050×7240×4125 |

| Power Supply | 380V 50hz |

LCH02: Advantages of the company’s self-developed 3D five axis cutting head:

1.Electric slip ring and gas slip ring ensure that the cutting head can rotate infinitely by n * 360 °.

2.The self-madegas slip ring ensures both air tightness and gas flow, which has higher reliability.

3.The cutting head with anti-collision function enables to effectively avoid damage to the equipment.

4.The cutting head with adaptive zoom capability enables to meet the requirements of cutting plates of various thicknesses.

Hot forming process analysis and simultaneous development

Hot forming process analysis and simultaneous development